Data Centre & Comms Room Clean

CAT Project Solutions Limited offer flexible data room cleaning solutions that will give you the confidence to know that your data centres & comms rooms are kept in an operational condition suitable to the equipment requirements and to avoid invalidating any manufacturer’s warranties. Many of the major manufacturers of IT hardware have clauses within their warranty documentation detailing the environmental conditions the equipment must be operated in.

![]()

Background

Background

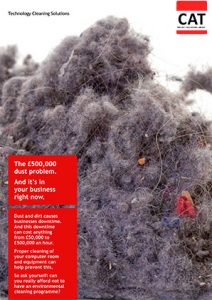

Contamination is an ever-present threat to sensitive data centre equipment. Its potential effects range from impaired power efficiency to catastrophic equipment failure. However, with the right expertise, prevention is entirely possible.

Contamination affecting ICT comes in two forms, particle matter (PM) and gaseous. These cause problems for many reasons. If PM blocks equipment cooling fans and heat sinks, they will work harder to keep equipment within operating temperature limits. This can increase a data centre’s power demand by 2% or more, as well as potentially shortening equipment lifetime and causing hardware failure due to overheating. Zinc whiskers and other PM can bridge between conductive tracks within electrical equipment, causing short circuits and hardware failures, a growing occurrence as ICT equipment shrinks in physical size, correspondingly reducing track bridging distances. Fibres longer than 5 mm have been found inside data equipment. Oxidisation arising from gas interaction can cause permanent corrosion, leading to irreparable equipment damage and failure.

Common contamination sources

External sources of contamination include cars, electricity generation, sea salt, natural and artificial fibres, plant pollens and wind-blown dust. Internal examples are particles from air conditioning unit fan belt wear, toner dust, packaging and construction materials, human hair and clothing, and zinc whiskers from electroplated steel floor plates. Contaminating gases occur naturally or result from industrial processes. They can either act alone or together with other gases or PM, forming compounds that oxidise metallic materials.

Contaminants enter the data centre through air conditioning units, open doors, on clothes and anything else brought into the room. Activities such as equipment maintenance or lifting floor or ceiling tiles can also release PM which can then reach ICT equipment through gravity, diffusion or electrostatic attraction.

Preventing downtime

Contamination prevention starts with the design of the data centre and surrounding areas. Relevant factors include using air handling unit filters, positive pressurisation, limiting the number of room entrances, using Takmats to capture footwear and trolley wheel dirt, sub floor area sealing and using suitable materials and fabrics within the data area. A policy for controlling and limiting visitors into the data area is also important.

Decontamination cleaning success depends on the frequency as well as the nature of the cleaning activities. Ideally, these should start before the first item of ICT or even associated hardware such as cable trays or suspended floors are installed. This is because cleaning areas consigned to such installations becomes more difficult or impossible once they are in place. And, clearly sensitive ICT equipment, once installed, will benefit from starting life in a clean environment.

After the data centre’s operational life starts, any cleaning schedule should allow for maintenance activities, which increase contamination levels.

Planning an effective cleaning program, in which both the schedule and nature of the cleaning activities are optimised, requires specialist knowledge of how locally prevailing conditions contribute to contamination problems, and how to prevent this. Therefore, working with a specialist data centre cleaning company is essential.

Using a general cleaning contractor or DIY may seem cheaper in the short term, but a critical lack of knowledge could cause serious downtime problems later.

Sustained protection

Particle sampling provides valid proof of room cleanliness at the time of measurement, but it doesn’t’ allow for any settled PM, or of contaminant later introduced into the area. An on-site risk assessment can reveal contamination sources, allow for nearby installations that could impact contamination levels, and check air filtration procedures.

Access policies for people and materials can also be reviewed. This information will contribute to a cleaning strategy cost-effectively matched to facility needs. Sustained protection of on-site equipment from contamination induced failures will be secured. The facility’s carbon footprint will also be reduced as unobstructed equipment cooling fans run more efficiently.

Using the right staff

CPS Limited will always use qualified and experienced staff, security clearance, training and expertise can be assured

All of our engineers can work safely around live ICT equipment. They use the right tools and cleaning products for the job; ensuring that anti static surface properties are not compromised, for example, we use highly filtered, specialist vacuum cleaners; ordinary cleaners blow out dust

The Service

The following is a brief outlined scope of works, prior to any works being undertaken CPS Ltd can offer a full method statement and risk assessment as required.

- All surfaces (including the underside of the ceiling) are vacuumed

- All services – trunking, plug points, AC units, gas suppressant systems etc. – are cleaned

- All woodwork is cleaned

- All glass is cleaned

- Racks are cleaned internally and externally, paying particular attention to the feet, and the lip of the doors where dust builds up.

- The floor void is vacuumed. Any defects found are reported back to the client. These may include rodent infestation, water leakage, loose legs etc.

- Floor tiles are either anti-static cleaned or polished – depending on the requirements of the client.

- Where the floor tiles are carpeted the tiles are treated with a solution to aid the anti-static properties of the room. This process also helps bond the fibres and as a result releases less fibres into the atmosphere.

- Where necessary we will clean the servers internally – particularly useful where contamination has occurred, or where the server trips out for no apparent reason.

In addition to the above the following is always applied.

- All vacuum equipment is HEPA filtered and regularly tested for performance.

- Cleaning cloths are micro fibre and anti-static.

- Cleaning solutions are nitrate and ammonia free.

- Any polish used is ultra high solid, and anti-slip, anti-static.

CPS are able to provide a full cleaning maintenance schedule to any site, going from a yearly clean up to having permanent staff on site. We can also provide protective material to help stop contamination including ‘Tacky mats’ and overshoes.

Environmental Testing

We can offer a full range of tests within the comms room / data centre, including.

- Humidity

- Levels of static electricity

- Particulate contaminates

- Zinc whiskers.

An independent laboratory is used to analyse the zinc whisker testing and to produce a report.